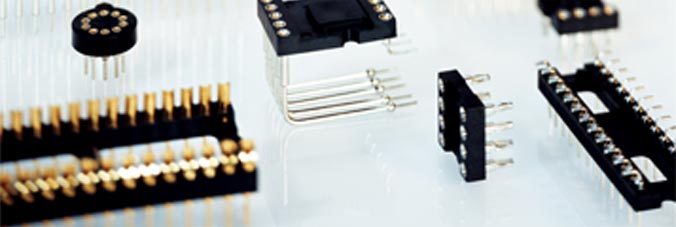

GENERAL SPECIFICATIONS

The values listed below are general specs applying for preci-dip DIL sockets. Please see individual catalog page for additional and product specific technical data.

OPERATING TEMPERATURE RANGE: -55 ... +125 °C

CLIMATIC CATEGORY (IEC): 55/125/21

OPERATING HUMIDITY RANGE: annual mean 75 %

MAX WORKING VOLTAGE: 100 VRMS/150 VDC

|

MECHANICAL CHARACTERISTICS |

|

| CLIP RETENTION | Min. 40 N (no displacement under axial force applied) |

| CONTACT (SLEEVE / CLIP) RETENTION | Min. 3.3 N acc. to MIL-DTL-83734, pt 4.6.4.2 |

|

PACKAGING |

|

|

|||||||||||||||

|

|||||||||||||||